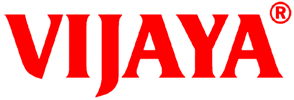

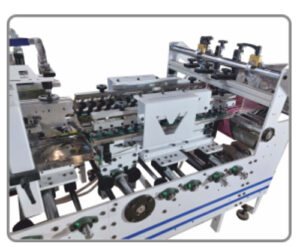

VIJAYA VEENINE CARTON FOLDER GLUER

A HIGH SPEED AUTOMATIC CARTON FOLDER GLUER WITH INDEPENDENT PRE FOLDING & CRASH LOCK BOTTOM UNIT WHICH MAKES LESS SETTING TIME FOR ALL TYPES OF CARTONS. THIS MACHINE CAN RUN DUPLEX, TRIPLY, STRAIGHTLINE, CRASH LOCK BOTTOM CARTONS, CACHE COVER, CD COVER, DOUBLE WALL CARTONS.

SALIENT FEATURES

- Separate motor & drive for feeder

- Vibrating arm

- Position imaging system

- Suction feeder belt with pump

- Independent Pre-folding unit

- Internationally accepted Advanced technology pre-folding apparatus system

- Pre-folding by folding belt & rod

- Three Transport tracks in two units for lock bottom system

- Glue flap grinder

- A & B pin separate glue tanks

- Speed variator for final folding belts

- Collapsable centre bottom track in final folding

- Batch counter with pneumatic kicker

- Touch screen operated advance technology panel

- Jamming sensor in transfer section

- Straightening device for outer carton

- 4.6 mtr. Pneumatically pressure operated delivery pressing station

- Pneumatically operated carton holding cylinders in pressing station

- Start stop operation pressing station

- Compatible for duplex, triply cartons

- Cache cover folding gluing attachment

- Double wall carton folding gluing attachment

- Pop corn carton attachment

- All timming belts driven

- 12mm solid sheet, CNC machined frame

- Anti vibration mounted pads

- Stand for electronic gluing system

- 3 Nozzle electronic gluing system with touch screen control

OPTIONAL FEATURES

- Plasma curing system

- Quality assurance system

- Braille embossing system

- Clapping device for corrugated cartons

FEEDER

- Electronic vibrating arm, separate motor & VFD with suction feeding belts : The feeding unit with variable speed & suction is designed to allow appropriate space between the cartons even at a very high speed.

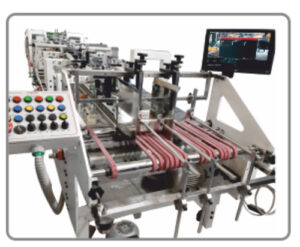

PRE- FOLDING UNIT

- For smooth opening of the carton at the time of filling on automatic filing / packing machine, the first and third crease can be pre-folded at 180' & 135" respectively. The unit is designed with side folding belt (Third crease) to avoid scratches on the cartons.

- Self adjustable transport tracks for duplex & E-fluited cartons

FINAL FOLDING UNIT WITH SPEED VARIATOR

- High speed precision design helps in accurate folding of second and fourth crease after gluing

- The speed variator device in final folding unit helps in varieing the speed of side belts as per the requirement of carton dimension to prevent wastage and miss registration of carton at high speed

- The highly performing design of folding belts & runner which plays a vital role in final finishing at a high speed

- Collapsible centre bottom track which can help to run smallest & the biggest carton without hassles

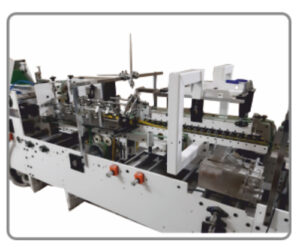

PRESSURE DELIVERY

- Pneumatic operated pressure system

- 4.5 mtr length with 3.1 mtr of effective pressure

- Separate motor for pressing station. The independent geared motor helps in increasing or decreasing the speed of unit. So that the different size of cartons comes between the pressure belts smoothly

- Upper conveyor can be moved forward and backward depending on the length of the carton.

- Optional Pneumatically operated carton holding system for outer carton cartons.

ALLIGNER UNIT FOR SIDE REGISTRATION

- Electronic vibrating arm, separate motor & VFD with suction feeding belts : The feeding unit with variable speed & suction is designed to allow appropriate space between the cartons even at a very high speed.

LOCK BOTTOM UNIT

- For folding of all lock bottom flaps this unit is designed in three transport tracks in 2 units, so that the carton remains under pressure of all three tracks at the time of folding of flaps for lock

bottom & four/six corner boxes. - This prevents shifting or non alignment of cartons resulting to low wastage and increases production speed.

- Self adjustable transport tracks for duplex and E-flute cartons.

TRANSFER SECTION

- It allows the carton to be transferred to pressure unit in regular, constant flow at any production speed

- Straitening device used to correct the registration of outer cartons.

- Equipped with touch control screen for the operating of the machine.

- Batch counter equipped with electronic sensor and pneumatic kicker

- Optional clapping device used for corrugated cartons

- Optional : Ejection for quality assurance system

Technical Specification of Machine |

|||

Models |

Power Required | Dimension |

Max. Speed |

VEENINE 65 |

12.5 KW | 1.3 mtr X 12.5 mtr |

300 mtr/m |

| VEENINE 80 | 15 KW | 1.5 mtr X 12.5 mtr |

300 mtr/m |

| VEENINE 102 | 15 KW | 1.7 mtr X 12.5 mtr |

300 mtr/m |

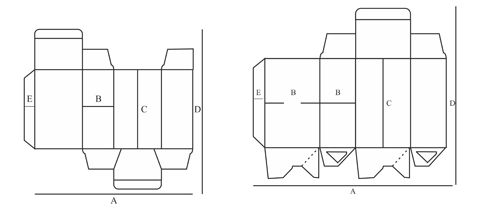

Technical Specification for STRAIGHT LINE CARTONS |

|||||||

Models |

A min. |

A max. |

B Min. |

B Max. |

C Min. |

D Max. |

E Min. |

VEENINE 65 |

60 mm |

650 mm |

15 mm |

250 mm |

55 mm |

450 mm |

11 mm |

| VEENINE 80 | 110 mm |

800 mm |

25 mm |

300 mm |

80 mm |

550 mm |

12 mm |

| VEENINE 102 | 140 mm |

1020 mm |

50 mm |

400 mm |

120 mm |

700 mm |

12mm |

Technical Specification for LOCK BOTTOM CARTONS |

||||||

Models |

A min. |

A max. |

B Min. |

C Min. |

D Max. |

E Min. |

VEENINE 65 |

140 mm |

650 mm |

32 mm |

90 mm |

450 mm |

11 mm |

| VEENINE 80 | 140 mm |

800 mm |

32 mm |

130 mm |

550 mm |

12 mm |

| VEENINE 102 | 160 mm |

1020 mm |

50 mm |

150 mm |

700 mm |

12mm |